Profiles

Xcimer: Manufacturing the Ultimate Energy Source

Xcimer is building a new generation of fusion power systems that aim to deliver limitless clean energy and power human progress. Founded by engineers Conner Galloway and Alexander Valys, their approach combines proven fusion science with innovative laser technology and modern engineering practices to make commercial fusion both achievable and affordable.

Dec 30, 2024

Powering Human Progress with Inertial Fusion

On the arc of progress, energy has driven almost every major advancement in human civilization. From steam engines to air travel, every leap in progress has come with rising energy use, growing 2–3% annually in the U.S. since the early 1800s—a trend known as the Henry Adams Curve. But since the 1970s, that trajectory stalled as the environmental costs of fossil fuels became clear and alternatives failed to emerge.

The promise of fusion energy—the same process that powers stars—could change this equation entirely. “With fusion, you’re essentially manufacturing energy as opposed to drilling for it,” explains Conner Galloway, CEO and CSO at Xcimer Energy. “The total amount of fuel consumed by a gigawatt-scale fusion plant for a year could be carried in the back of a pickup truck versus many mile-long trains of coal. There’s millennia supply of fusion fuels in the Earth’s crust and oceans, making it the ultimate energy source to propel humanity forward.”

From Government Labs to Commercial Innovation

For Conner and Alexander Valys, now President and CTO, the path to founding Xcimer started at Los Alamos National Laboratory. There, they learned about decades of progress in laser inertial fusion made during the Cold War and became convinced it was the most practical path to commercial fusion power.

Their insight built on three overlooked breakthroughs:

- Proving Fusion Ignition (1980s): The Halite-Centurion program achieved ignition and significant gain using x-rays in underground tests. It proved fusion works with a large-enough fuel pellet, but replicating the results with a 10 megajoule laser as recommended by the National Academy of Sciences was too expensive.

- High-Energy Lasers for Missile Defense (1980s): Significant defense program R&D advanced low-cost, high-energy excimer lasers, but the systems were shelved after the Cold War ended.

- Laser Pulse Compression (1970s): Soviet researchers developed Stimulated Brillouin Scattering (SBS), a technique to shorten laser pulses, but the work drew little attention in the West.

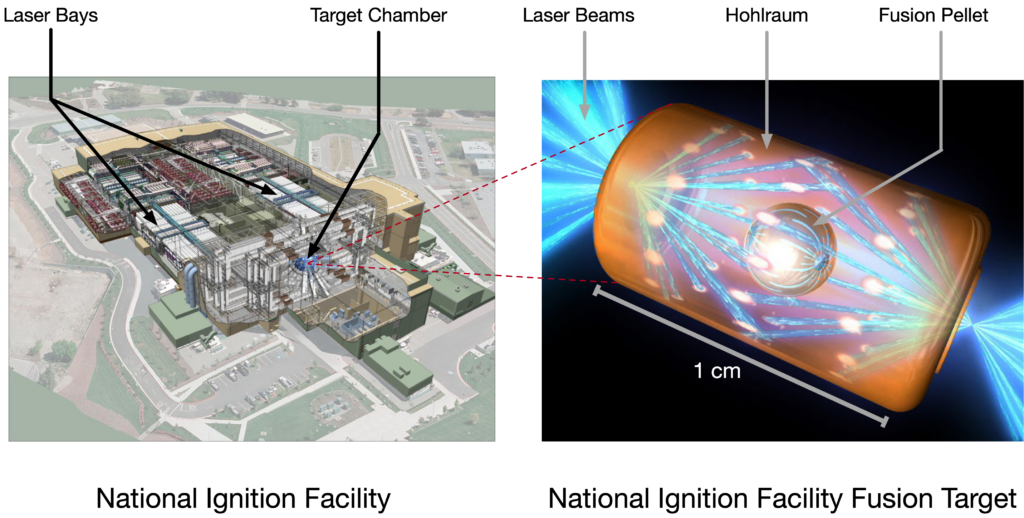

Fast forward to December 2022, when the National Ignition Facility (NIF) achieved ignition with a 2-megajoule laser—but just barely. NIF reached the minimum threshold for ignition but lacked the energy to produce commercially viable gains. A 10-megajoule system, as initially recommended, remained out of reach due to cost constraints.

Xcimer’s founders saw their opening. By combining excimer lasers with Soviet pulse-compression techniques, they could deliver the higher energy required without the costly optics and fragile components holding others back.

“Learning about all of the progress made in government labs was eye-opening,” recalls Conner. “While the Halite-Centurion tests proved inertial fusion works, the Soviet paper gave us confidence we could compress excimer lasers down to the nanosecond timescale needed without expensive components.”

Designing for Commercial Viability

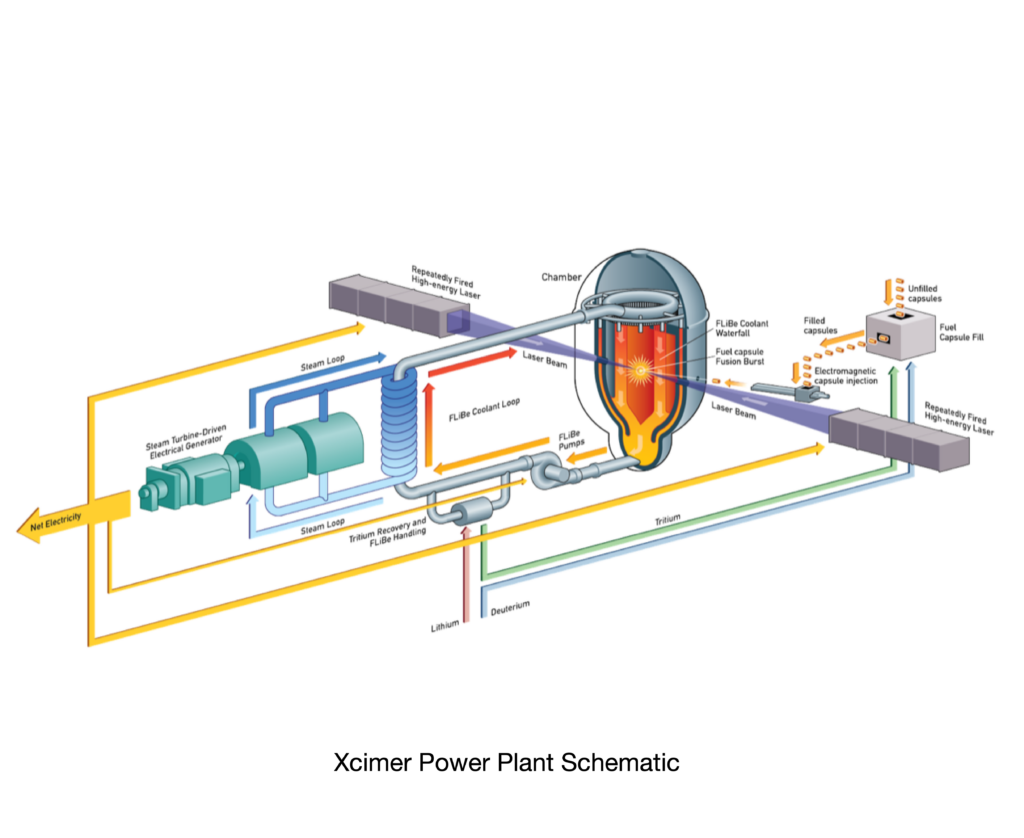

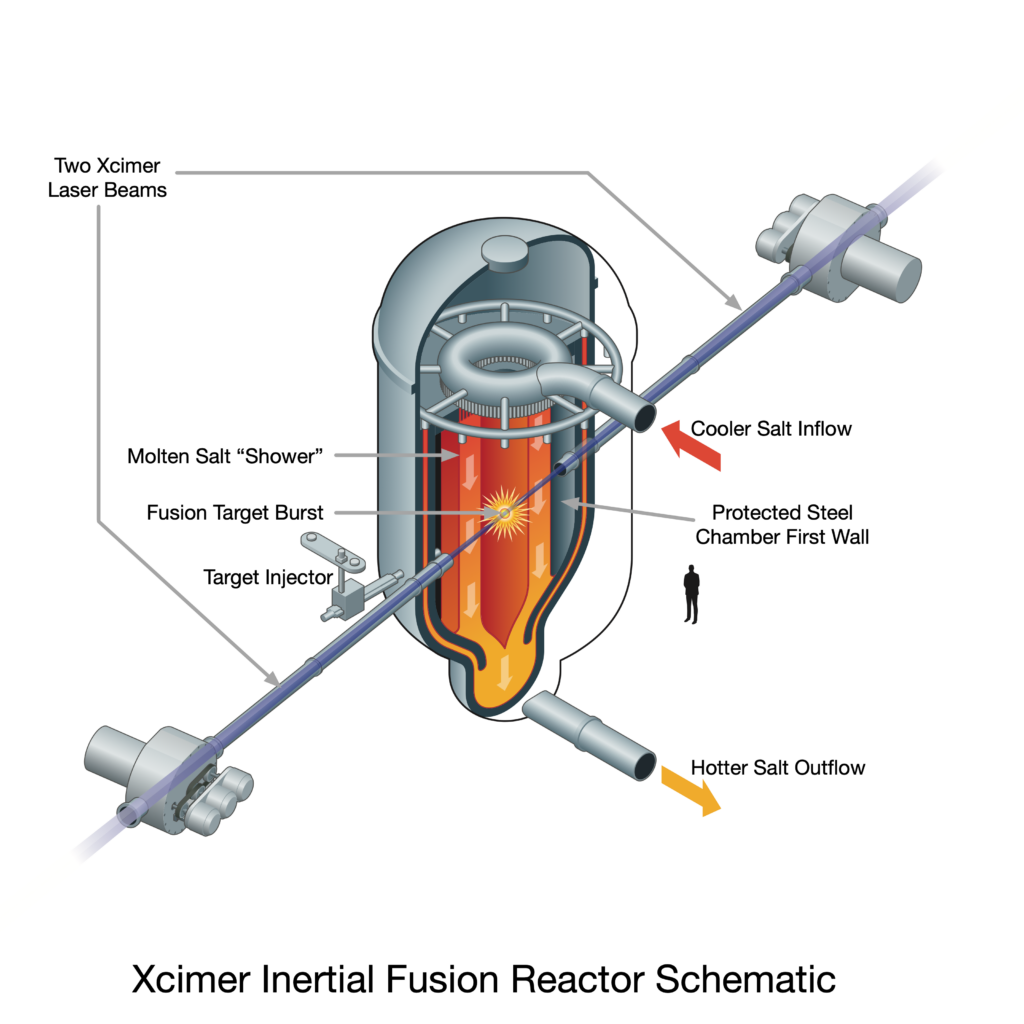

Xcimer’s system starts with the fuel source: deuterium from ordinary water and lithium found abundantly in the Earth’s crust. Inside a vacuum chamber, a fuel pellet—about the size of a ball bearing—is targeted by two powerful excimer lasers. The laser beams pass through small gaps in a “waterfall” of molten salt that falls down inside the chamber. When the lasers hit the target, they compress the fuel to extreme temperatures and pressures in billionths of a second, triggering a burst of fusion energy. The molten salt, which looks like a transparent liquid shower and protects the chamber walls from direct exposure to the fusion bursts, captures this energy and carries it out of the system to power conventional steam turbines and generate usable power.

The key to making this system commercially viable is the laser design. “For a commercial plant, we’re talking about something like 12 megajoules on target from 2 simpler lasers versus NIF’s 192 more expensive lasers,” says Alexander. “That’s roughly the energy of a fully loaded 18-wheeler traveling at highway speeds, delivered in a pulse of light a few billionths of a second long.”

This higher energy approach simplifies the entire system. “Traditional designs require extremely precise manufacturing and frequent shots—10 to 15 targets shot per second,” explains Alexander. “Our approach allows for larger fuel pellets with looser tolerances, and we only need one shot every few seconds. This means simpler engineering, less wear on components, and lower operating costs. It’s about designing for commercial viability from the start.”

Learning Fast, Building Smart

The challenge for Xcimer comes down to scale. The science works—national labs have proven that. Now they need to build these systems large enough for commercial power generation while keeping costs manageable. Xcimer’s started by validating the core technology. Through table-top experiments at the University of Illinois, they proved the Soviet pulse-compression technique works and can be used with excimer lasers. Now they’re building a testbed at their 70,000-square-foot Phoenix facility in Denver.

Rather than building Phoenix to test a single operating point, they designed it as a flexible learning platform. “Early in planning Phoenix, we had a single configuration we wanted to test,” explains Alexander. “But when we realized it would take two years and tens of millions of dollars to build, our technical advisors asked: What if our understanding changes? What if we need to explore different parameters? So we deliberately redesigned Phoenix to be more flexible from the start.”

This philosophy shaped every aspect of the facility’s design. The team carefully considered what they could test quickly at small scale to inform the larger system’s development. They built in modularity and expansion paths to explore different energies, pressures, and angles. “Even after we achieve our headline results, Phoenix will continue serving as a rapid iteration and experimentation platform,” says Alexander. “It’s about maximizing what we can learn at each stage.”

Building the Future of Energy

What sounds like a lofty moonshot looks more like a practical blueprint when examining Xcimer’s methodical approach. The Department of Energy (DOE) recognized this potential in 2023, awarding Xcimer $9 million through their Milestone-Based Fusion Development Program for pilot-scale demonstrations.

To tackle their complex mission, Xcimer is building a team that combines fusion expertise with practical engineering experience. They recently brought on Giovanni Greco as SVP of Engineering, who led development of pioneering aerospace systems at Blue Origin and Astra Space. This mix of scientific credentials and engineering know-how strengthens their ability to tackle complex challenges at scale.

“We’re not doing this alone,” notes Alexander. “There’s a huge pool of experience at the national laboratories and other organizations that have been thinking about this for decades. We’re a decade away from commercialization, which is why we’re forming partnerships early to expand supply chains and move the industry forward.”

Mike Schroepfer emphasizes the practical nature of Xcimer’s approach, “This sounds audacious, yet humans have already achieved fusion at the National Ignition Facility. There are promising experiments showing this is possible. What’s exciting about Xcimer is they’re showing how to make it commercially viable and scalable.”

For Xcimer’s founders, commercializing fusion reflects their broader vision for humanity’s future. “There’s no other technique more efficient at converting available mass-energy to useful work until you get to black hole engineering, which is a very long time away, if ever.” explains Conner. “So, this is how we’ll power humanity’s next great leap forward and even propel ourselves to the stars.”